A Short History

A Short History

A Short YJ History…

The 1995 YJ Wrangler in Sport trim with full steel doors. The squared-off rear of the “family” sport cage that came in 1992 can be seen here. Early versions had an angular CJ style.

The first Wrangler…

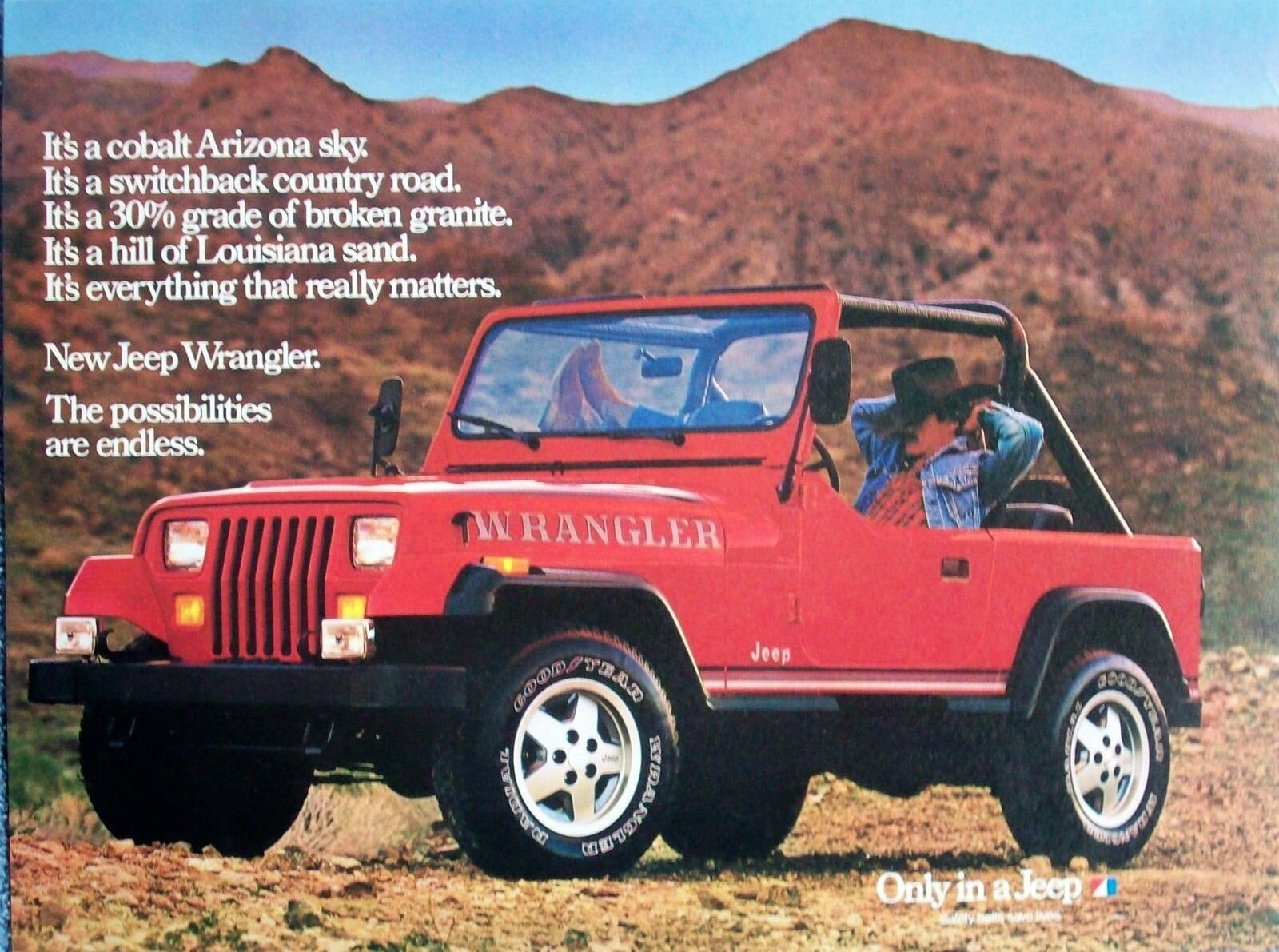

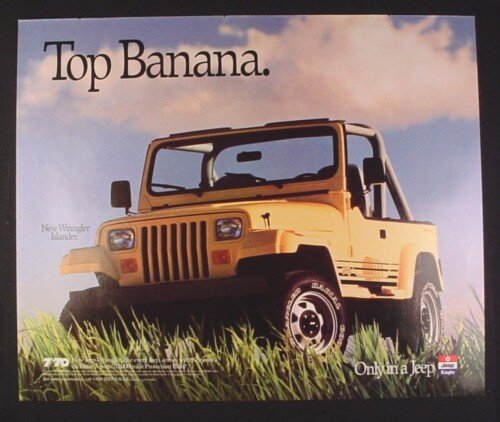

The Jeep YJ Wrangler was actually designed by the American Motors Corporation prior to being purchased by the Chrysler Corporation in 1987. The YJ was the replacement for the long-running CJ series. The Wrangler was, in truth, only an evolution of the CJ. However, as with most new Jeep model debuts, Jeep aficionados decried it as “not a Jeep”. Majority of the furor came from the square headlights and the soft dash design. Most previous Jeep products, and all CJs, had been produced with round DOT sealed beams and a flat steel dash. The switch to square headlights in Jeep’s iconic open top 4x4 resulted in surprisingly tectonic levels of furor amongst the faithful. Since it had just been introduced prior to the $1.5 billion buyout of AMC by Chrysler, the square headlights were unfairly blamed on Chrysler. AMC had been in the process of modernizing its meager vehicle line by changing designs. The YJ Wrangler and XJ Cherokee are the most recognizable. Although the square headlight controversy was put to bed when the TJ Wrangler was unveiled, the only square headlight Wrangler has aged well, and even loved by owners for this uniqueness. “It’s hip to be square” decals and printed T-shirts circulate to this day.

The YJ added some features not well received by some purists, but did widely expand sales of the short wheelbase 4x4 as have current iterations. On-road handling, stability, and ride was significantly better than the CJ while some improved creature comforts improved daily life with Jeep. Available hard top as well as air conditioning and more comfortable high-back seats with a padded dash and improved instrumentation were welcomed by most. A new shift-on-the-fly chain driven transfer case and vacuum disconnect front axle eliminated getting out of the Jeep to “lock in the hubs” every time 4x4 was needed. 3 years into production, fuel injection became standard on the YJ. This dramatically improved drivability in all terrains and further improved reliability in the tried but true inline 6 and 4 cylinder motors. Some questionable transmissions were used early in the production run, but was generally rectified by 1990.

It’s important to remember that the YJ Wrangler is an old platform. Its debut was in 1987 with the “newest” YJs now being OVER 20 years old! There is a lot to love about the YJ, though. It is the crossroads between the historic CJ and more modern Jeeps. The main reason for this is the retention of a leaf spring suspension and simple wiring harnesses with the addition of electronic fuel injection and some comfort points. Aftermarket support of the YJ isn’t what it once was, but they are still very rebuildable and easy to modify. Parts are still readily available in local stores, and the design itself remains reasonable to repair and maintain indefinitely. YJs, like most Jeeps, also lend themselves well to axle and drivetrain swaps as these kind of serious modifications are done on a seemingly daily basis for various reasons.

Ultimately, the reasons stated above are the reason most people still purchase and operate older Wranglers and CJs. The vehicle does have an open-ended lifespan for all practical purposes- particularly when maintained properly. The original vehicles are comparatively simple products with acceptably robust components in stock form and have very long lifespans. More powerful or modern powertrains can be swapped into the chassis if desired, suspensions can be easily replaced or upgraded while even frames and bodies can be replaced. You can’t do that with a contemporary unibody vehicle. Continue reading to see how “Big Blue”, the Flatwater Jeep YJ came to be. It’s had an interesting life.

Drivetrain

Drivetrain

The Drivetrain

Some well-founded accusations have been made that I own a large Lego set, not a Jeep…

Perhaps the most important part of a Jeep build is the drivetrain. Even the engine isn’t a top concern if the rest of the system is properly set up for the intended use. If you are unfamiliar with how Jeeps and other off pavement 4x4s are commonly modified, it’s important to remember that no modification happens in a vacuum. What that means is that one modification always leads to another to maintain balance. It’s true that quite a few modified 4x4s are downright unsafe on the road and prone to major failures. You can’t just bolt on a bunch of doodads and hope for the best. Another aspect of this is that if someone is putting together a purpose-built rig, it’s easier. A rock crawler isn’t expected to drive long distances at highway speed, and a mud truck isn’t expected to be able to do controlled crawling. However, unless your 4x4 is a trailer queen meant for one thing, maintaining a safe balance of performance and reliability is a difficult and expensive proposition. For long distance overland use, striking the right balance is even more a challenge.

Building a YJ capable of unsupported, long-distance backcountry travel in all weather conditions has been the aggressive goal. Perhaps a YJ is not the ideal platform for such endeavors due to the lack of cargo capacity and “spartan” comfort levels. I’ll definitely own that. Overlanding experience with the YJ is a reason I now have a Jeep WK2 Grand Cherokee set up for overland travel. But, there really is nothing like exploring wild places in an open top short wheelbase Jeep. That cannot be overstated. What is now popularly called “overlanding” is the reason I first bought a Jeep back in the late 1990s. I wanted a capable, fun, 4x4 that could take me far into the backcountry for camping and adventure activities over long distances. However, most of these adventures would require a day or more of driving just to get to some locations. I did go through a phase of local “sport wheeling” in which the blue YJ was modified for use in local off-road parks, but I came back around to the long-distance, do-anything philosophy.

To this end, some major drivetrain modifications were undertaken over many years. Instead of going through the whole process, I will focus on the end result, and why. The final and current drivetrain configuration is a Jeep inline six “stroker” of 4.6 liters displacement mounted to an AW4 automatic with overdrive from an XJ Cherokee. The transfer case is a NP231HD from JB conversions with a super short output. The rear axle has been upgraded to a Ford 8.8 from a 97 Explorer with disk brakes and an Eaton E-Locker with 4.10 gears. The OEM Dana30 front axle is retained, but has been upgraded with TJ half shafts, upgraded brakes, an OX Locker with 4.10 gears, and heavy duty steering linkage.

Suspension

Suspension

Suspension

Here is Greer enjoying some exploring in Big Blue. This trip was his first exposure to technical 4x4 driving.

Is it really a Jeep without a lift…

When most people think of a Jeep, it’s typically a modified rig with meaty tires and a lift. While a factory stock Jeep is comparably quite capable in it’s own right, I don’t know of many enthusiasts who keep one that way. The short wheelbase Jeep really is the granddaddy of modified 4x4s and the incredible aftermarket we see today for off pavement vehicles came from the desire to maximize the performance of Jeeps. For a little background into how much things have changed, consider what has transpired since the 1980’s.

I was first indoctrinated into “Jeeping” in the early 1990’s in Arizona. Back then, if you had a small “lift kit" in the 2.5” territory with bigger tires and a winch- you were a serious Jeeper. If you had a bigger custom lift in the 4” range and 33” tires with locking differentials, or ‘gasp’ axle swaps- well, that was “hard core” at the time. Yes, there were still some off the shelf lifts with shiny wheels and bumpers for the poseurs, mainly because even more so at that time, real off road components were comparably as expensive as a whole to another Jeep. Flash to current day when factory lockers, 33” tires, low geared transfer cases, and winch bumpers are factory option packages.

Big Blue has had a lift since it was first purchased, but has had the springs replaced a couple times. Currently, it is running on custom spring packs made by my local Alcan Spring. This became a necessity due to the extra weight of all the modifications and the frequent towing of the Pioneer overland trailer. I had installed and even built up some Fabtech springs prior to the big CDR adventure that were in the 3.5” territory. They worked well at first, but were seriously sagging about halfway into the CDR due to the hard offroad trailer towing. They were temporarily beefed up in Montana, but were still far from ideal.

All the overland gear and armor the YJ had accumulated over the years pushed it over capacity what was generally available for off the shelf suspension kits. The only intelligent thing to do was to have some custom springs built that actually matched the gross expedition weight of the vehicle. The Jeep was weighed per axle fully loaded at our local port of entry, and an expensive trip was made to Alcan. The springs they produced matched the original lift in order to bring driveshafts back into proper angles and the suspension travel to where it should be. I cannot overstate how transformative these springs have been to the driveability and ride of the Jeep overall. Several passengers have even commented on how they have never ridden in a Wrangler with this good of a ride. If you are building a custom platform, custom springs matched to your vehicle should be your only serious consideration in the suspension part of the equation.

Armor

Armor

Armor

It all started when…

The following is placeholder text known as “lorem ipsum,” which is scrambled Latin used by designers to mimic real copy. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque congue porttitor ullamcorper. Maecenas non leo laoreet, condimentum lorem nec, vulputate massa. Integer tempus, elit in laoreet posuere, lectus neque blandit dui, et placerat urna diam mattis orci.

Vivamus a ante congue, porta nunc nec, hendrerit turpis. Aliquam bibendum, turpis eu mattis iaculis, ex lorem mollis sem, ut sollicitudin risus orci quis tellus. Vivamus a ante congue, porta nunc nec, hendrerit turpis. Mauris egestas at nibh nec finibus. Mauris egestas at nibh nec finibus.

Electrical

Electrical

Electrical

It all started when…

The following is placeholder text known as “lorem ipsum,” which is scrambled Latin used by designers to mimic real copy. Sed a ligula quis sapien lacinia egestas. Quisque congue porttitor ullamcorper. Mauris id fermentum nulla.

Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae. Vivamus sit amet semper lacus, in mollis libero. Mauris id fermentum nulla. Nulla lectus ante, consequat et ex eget, feugiat tincidunt metus. Donec eget risus diam. Phasellus sodales massa malesuada tellus fringilla, nec bibendum tellus blandit.

Cargo and Convienence

Cargo and Convienence

Cargo and Convenience

It all started when…

The following is placeholder text known as “lorem ipsum,” which is scrambled Latin used by designers to mimic real copy. Maecenas non leo laoreet, condimentum lorem nec, vulputate massa. Vivamus sit amet semper lacus, in mollis libero. Vivamus a ante congue, porta nunc nec, hendrerit turpis. Mauris id fermentum nulla. Donec eu est non lacus lacinia semper.

Vivamus a ante congue, porta nunc nec, hendrerit turpis. Fusce at massa nec sapien auctor gravida in in tellus. Maecenas non leo laoreet, condimentum lorem nec, vulputate massa. Mauris id fermentum nulla. Quisque congue porttitor ullamcorper. Mauris id fermentum nulla. Phasellus sodales massa malesuada tellus fringilla, nec bibendum tellus blandit.